Converting CO₂ into Profit: 8,000 tons per container

FormiCarbon's modular reactors process 8,000 tons of CO₂ per container annually, helping biogas plants.

.png)

ISO-standardized modular reactor converting CO₂ into formic acid

Converting CO₂ into Value: The Process

FormiCarbon's process transforms waste CO₂ from biogas plants into high-purity formic acid through a continuous hydrogenation reaction, powered by our proprietary Supported Ionic Liquid Phase (SILP) catalyst technology.

- Mild Operating Conditions: 25–100°C and 1–40 bar, designed for safety, energy efficiency, and compatibility with existing infrastructure.

- Industrial-Grade Output: 85–94% formic acid equivalence (as free acid), tailored for applications from hydrogen storage to chemical synthesis.

- Proven Long-Term Stability: 112+ days of continuous catalyst operation validated in lab conditions, with recovery rates exceeding 99.8%.

- Energy-Efficient: <1 MWh per year—a fraction of the energy required by traditional electrolysis or Power-to-X pathways.

The Chemical Transformation

The core reaction is elegantly simple: CO₂ + H₂ ↔ HCOOH (Formic Acid)

Our SILP technology makes this reaction continuous, selective, and economically viable, even at industrial scale.

Supported Ionic Liquid Phase (SILP) Technology

At the heart of FormiCarbon's system lies our proprietary SILP catalyst technology, a breakthrough that enables continuous, high-efficiency CO₂ conversion with unprecedented stability and minimal operational costs.

Exceptional Catalyst Lifespan

Our Ru-PNP catalyst achieves >99.999% recovery per cycle, ensuring long-term performance and dramatically reducing replacement costs compared to conventional systems.

Ultra-Low Energy Demand

SILP technology operates at mild temperatures (25–100°C) and low pressures (1–40 bar), consuming <1 MWh per year of continuous production per container hence up to 100x less energy than electrolysis-based alternatives.

Seamless Scalability

Unlike batch processes, SILP enables truly continuous production, maximizing output and minimizing downtime for consistent, high-purity formic acid generation.

How SILP Technology Works

SILP immobilizes our proprietary Ru-PNP catalyst in a thin ionic liquid layer on a porous support. This design:

- Locks the catalyst in place, preventing degradation or leaching

- Enables continuous gas-phase reactions as CO₂ and H₂ flow through the catalyst bed

- Maintains high selectivity and conversion over extended operation

- Simplifies product separation with minimal downstream processing

Why SILP Outperforms Traditional Catalysis:

- No complex catalyst separation steps

- Operates at a fraction of the energy cost

- Inherently continuous and scalable

- Stable under industrial conditions

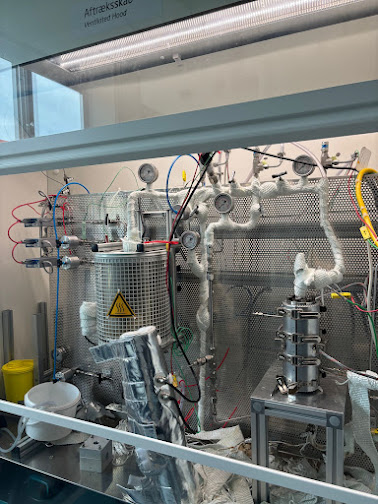

Laboratory-scale SILP reactor demonstrating continuous CO₂ hydrogenation

Technology Readiness

Currently at TRL 4, with proven continuous operation and validated conversion efficiency in laboratory conditions. Pilot-scale demonstrations are underway.

Performance Highlights

- Catalyst Stability: 112+ days continuous

- Catalyst Recovery: >99.999%

- Operating Range: 25–100°C, 1–40 bar

- Energy Efficiency: <1 MWh/year

Containerized, Scalable Architecture

FormiCarbon's reactors are designed as ISO-standardized shipping containers, enabling rapid deployment, linear scalability, and minimal on-site infrastructure requirements.

- Plug and Play Deployment: Install directly at biogas facilities with minimal setup

- Open Source Design: AGPL v3+ licensed hardware and software reduces vendor lock in

- Remote Monitoring: Full telemetry and control systems for optimized operation

- Linear Scalability: Add containers as CO₂ output increases

Capacity Per Container

Supply Chain Components

Built with industry-standard, reliable components:

- • pH Sensors: Atlas Scientific

- • Sensor and Electronics: Pimoroni

.png)

ISO-standardized containerized reactor ready for rapid deployment

Operational & Capital Efficiency

FormiCarbon's containerized system delivers exceptional operational efficiency with low capital requirements, enabling rapid payback periods and scalable deployment across multiple biogas facilities.

Operational Efficiency (OPEX)

Extremely Low Energy Consumption

SILP catalyst technology requires minimal electrical power compared to traditional Power-to-X systems, operating at mild temperatures (25–100°C) and low pressures (1–40 bar).

High Catalyst Recovery

With >99.9992% catalyst recoverability, catalyst replacement costs are virtually eliminated, ensuring stable long-term operations.

Minimal Maintenance

Open-source hardware and modular design reduce maintenance complexity, with remote monitoring capabilities minimizing on-site intervention.

Continuous Production

Demonstrated 112 days of continuous operation in lab trials, ensuring consistent output and revenue generation.

Capital Efficiency (CAPEX)

Modular Containerization

ISO standard containers enable rapid deployment, factory assembly, and linear scalability. Each unit processes 8,000 tons CO₂ per year.

Open-Source Architecture

AGPL v3.0+ licensing eliminates vendor lock in, reduces component costs, and enables in house maintenance and upgrades.

Decentralized Deployment

On site installation eliminates transportation infrastructure costs. Containers ship directly to biogas facilities.

Scalable Investment

Start with one container and expand incrementally based on CO₂ availability and market demand.

Open-Source & Embedded Systems

Building for Transparency and Reliability

We believe in transparency, collaboration, and long-term reliability. By open-sourcing our hardware and software under AGPL-v3.0+, we empower users to customize systems, reduce vendor lock-in, and participate in community-driven innovation.

Serious about open source: All derivatives must remain open under AGPL-v3.0+. This ensures transparency and prevents proprietary forks.

FormiCarbon's technical stack integrates Rust-based embedded systems for reliability, open-source hardware architecture for transparency, and modular deployment across distributed containers - further enhancing scalability and maintainability of our CO₂-to-formic acid conversion technology.

Memory Safety with Rust

We use Rust for all embedded systems to ensure compile-time memory safety, zero-cost abstractions, and elimination of common bugs like buffer overflows and data races.

Powered by Embassy, a modern async-capable embedded HAL for Rust.

Target Platforms

- RP2350 – Low-level control, valve actuation, temperature & pressure monitoring

- Revolution Pi 5 – High-level logic, data logging, remote communication

- iCE40 FPGA (optional) – Time-critical tasks with open-source toolchains

Sensing & Control Architecture

Hardware

- RevPi & RP2350 controllers

- ICP-10125 pressure sensors

- Hydraulic flow sensing

- MAX31865 RTD amplifier

- Atlas Scientific pH probes

Software Stack

- Embassy async runtime

- I²C, SPI, UART

- PID control loops

- MQTT & Modbus/IP

- Real-time data logging

Key Benefits

- Memory safety guarantees

- Deterministic behavior

- Modular & scalable

- Auditable code

- Long-term reliability

Join the Community

We invite developers, researchers, and partners to contribute to our open-source repositories, suggest improvements, or adapt our designs for your applications.

Repositories: Available on Codeberg (with GitHub mirror) - TO BE ADDED LATER!

Want to contribute more officially? Reach out to formicarbon@gmail.com

Environmental Impact & Circular Economy

FormiCarbon creates a true circular economy by transforming waste CO₂ into valuable industrial chemicals, eliminating emissions and generating revenue simultaneously.

Carbon-Negative Production

Our process achieves net negative carbon emissions by converting CO₂ that would otherwise be vented or require expensive capture and storage.

Preliminary LCA Disclaimer

These figures are based on preliminary Life Cycle Assessment (LCA) assumptions and require proper verification and third-party validation. Current assumptions include:

- Extraction: Ruthenium catalyst (33,005 kgCO₂eq/kg; 0.01 kg per ton FA)

- Production: Formic acid credit (-4.585 kgCO₂eq/kg), CO₂ feedstock (-1 kgCO₂eq/kg), green hydrogen (4.5 kgCO₂eq/kg), stainless steel scrap (5.986 kgCO₂eq/kg), ionic liquid (1 kgCO₂eq/kg), natural gas heat (0.08147 kgCO₂eq/MJ)

- Recycling: 50% ruthenium recovery (17,000 kgCO₂eq/kg; 0.001 kg per ton FA)

- Comparison baseline: Traditional formic acid (ammonium sulfate byproduct method) ~+580 kgCO₂eq/kg

*Based on preliminary LCA calculations. Traditional FA emissions primarily from ammonium sulfate byproduct generation.

Formic Acid Applications

Our high-purity formic acid serves critical roles across multiple industries:

Agriculture & Animal Feed

Silage preservation, feed acidification, and antibacterial treatment

Apiary Anti-Mite Treatment

Important for controlling Varroa mites in beekeeping

Textile Manufacturing

Dyeing processes, leather tanning, and fabric finishing

Aviation Deicing

Important ingredient for deicing agents used for aviation.

Chemical Synthesis

Intermediate for pharmaceuticals, pesticides, and specialty chemicals

Energy Storage

Liquid hydrogen carrier for fuel cell applications

Market Size & Opportunity

The European formic acid market is valued at €1.7 billion (DKK 13 billion), with growing demand from environmentally conscious buyers seeking verified low-carbon alternatives.

Competitive Advantages

FormiCarbon's unique combination of SILP catalyst technology, open-source architecture, and modular containerization creates defensible competitive moats in both CO₂ utilization and formic acid production markets.

Energy Efficiency Breakthrough

Our SILP technology operates at 100x lower power consumption than traditional Power-to-X approaches, dramatically reducing operational costs and carbon footprint.

Exceptional Catalyst Recovery

Patented Ru-PNP SILP catalyst maintains stability over 112+ days of continuous operation with near-perfect recovery rates, minimizing replacement costs.

Open-Source Protection

AGPL-v3+ licensed hardware and software prevents vendor lock-in while protecting IP through copyleft licensing, ensuring customer flexibility and long-term viability.

Decentralized Deployment

ISO container format enables on-site installation without infrastructure changes. Each container processes 8,000 tons CO₂/year independently with linear scalability.

Mild Operating Conditions

Operation at 25–100°C and 1–40 bar reduces safety risks, insurance costs, and energy requirements compared to high-temperature/pressure alternatives.

Development Roadmap

2025–2026: Validation Phase (TRL 4 → TRL 6)

Catalyst Validation: Quantitative analysis of catalyst stability, conversion efficiency, and long-term performance.

Pilot Container Development: Design, manufacture, and deploy first pilot-scale containerized reactor.

IP & Open-Source Strategy: Finalize intellectual property positioning while maintaining open-source hardware/software principles.

Regulatory Compliance: Secure necessary environmental permits and safety certifications for commercial operation.

Market Validation: Demonstrate commercial viability and customer retention across multiple deployment sites.

2027–2029: Expansion Phase (TRL 7 → TRL 8)

Product Diversification: Validate and productionize methanol synthesis pathway using same SILP platform technology.

Supply Chain Optimization: Establish partnerships with green hydrogen suppliers and formic acid off-takers.

Manufacturing Scale-Up: Transition from pilot production to standardized container manufacturing.

2030+: Industrial Scaling (TRL 9)

Industrial Process Integration: Deploy containerized reactors at large-scale industrial CO₂ emission sources beyond biogas.

Technology Platform Expansion: Adapt SILP catalyst technology for additional carbon-based chemical production pathways.

Funding Strategy

Validation Phase (2025–2026)

Soft funding, grants, and early-stage venture capital to support pilot container deployment and catalyst validation.

Expansion & Scaling (2027+)

Industry partnerships, growth equity, and revenue financing to support multi-container deployments and geographic expansion.

Partner With Us

FormiCarbon is seeking strategic partners, early adopters, and investors to accelerate the deployment of sustainable CO₂ utilization technology across Europe.

Biogas Plant Operators

Transform your CO₂ tax burden into revenue. Early adopters receive preferential pricing and collaborative development opportunities.

- Free CO₂ removal service

Chemical Off-Takers

Source low-carbon formic acid at competitive prices. Support your sustainability goals with verified carbon-negative chemicals.

- DKK 4,100 per ton pricing

- 4.79 tons CO₂ removed per ton FA

- Traceable carbon credentials

- Local supply chain benefits

Investors & Funders

Join us in scaling proven technology with strong unit economics and clear path to profitability. ESG-aligned investment with measurable impact.

- TRL 4 validated technology

- Growing CCS/CCU market

Get in Touch

Help Shape the Future of Low-Carbon Formic Acid

What This Survey Is About

This survey is conducted by FormiCarbon, a startup from the Technical University of Denmark (DTU), focused on converting captured CO₂ emissions into high-purity formic acid, a chemical widely used in agriculture, textiles, leather processing, and industrial applications.

Our Goal

We want to understand how your organization currently sources formic acid, what matters most to you (price, purity, reliability, environmental impact), and whether you'd be interested in switching to a sustainable, low-carbon alternative.

1–2 minutes

Completely anonymous

Shape sustainable chemistry

Your responses will help us understand industry needs and shape a sustainable, high-quality formic acid product that delivers real environmental impact.

Your responses are anonymous and confidential. We'll use your feedback to validate market demand, refine our product roadmap, and secure funding for faster deployment.